In order to find out the reason why Limbaži residents do not dress in countless sweaters during the winter months and do not wear several socks from their grandmother, it was decided that the students of the Limbaži Science Team will conduct an interview with Valters Mardoks, Production Director of Limbažu siltums LTD.

Limbazi is the old city of the Hanseatic League, the former administrative center of the so-called Liv End of the Archbishopric of Riga and the residence of the Archbishop of Riga 14-16. century. Area: 8,994 km² and ~ 7 thousand inhabitants.

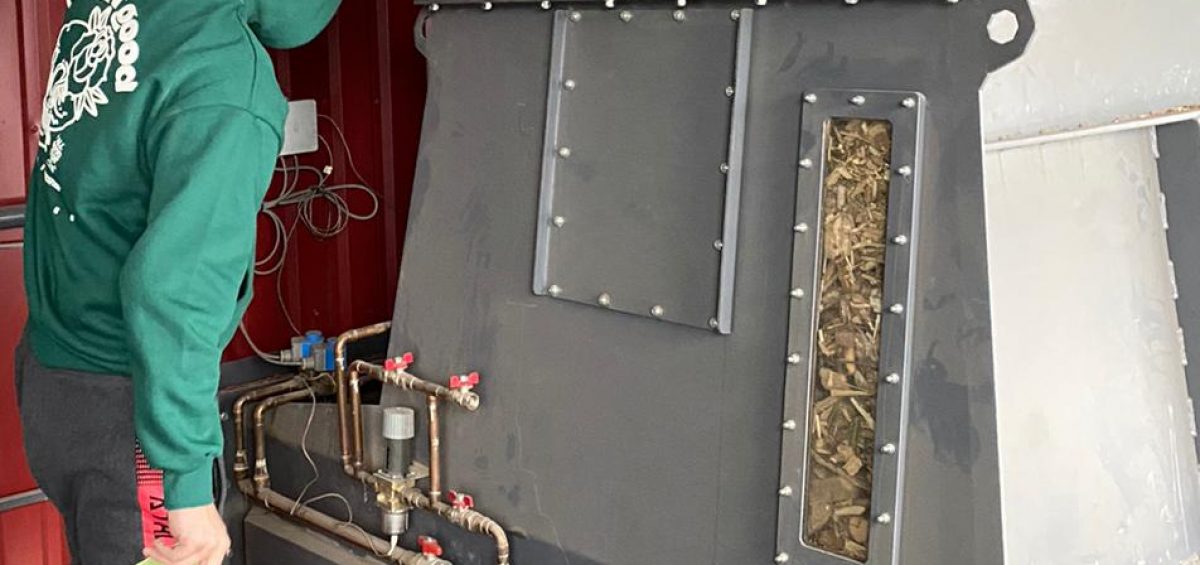

Limbažu siltums LTD. provides heat energy to the residents of Limbaži city, institutions, if they are connected to the district heating supply. There are about 2 thousand customers, about 200 objects are connected – apartment houses, private houses, shops, institutions, etc.

The positive aspects of district heating are more efficient production process, lower costs, cheaper service, environmentally friendly, because they clean flue gases with special filters, reduce CO2 emissions. Škelda is a local fuel material, a renewable resource available in Latvia. Residents of Limbaži are not dependent on the supply of gas, oil or coal from another country. This is essential in today’s political and economic context.

We do not see the negative aspects of wood chips as a material. For the process as a whole, it is difficult to connect new customers to the district heating system that are far from the district heating network, which is costly.

Science team reporters also learned some interesting facts about the company.

- Limbaži siltums heat is obtained only from wood chips, while wood chips are obtained from local logging.

- In the past, 37% of heat losses were in the city of Limbaži but now they have been eliminated by 10%.

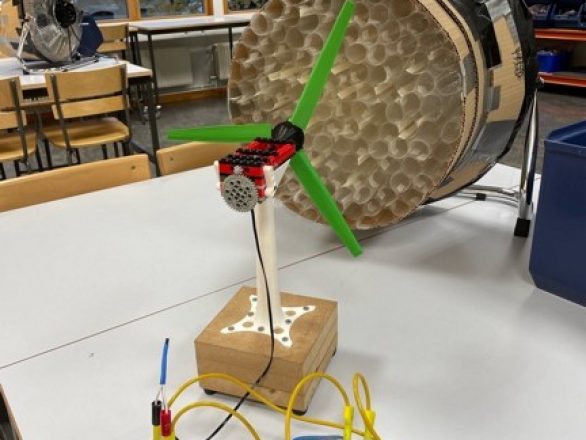

- In Limbaži, it is also planned to use alternative energy production using solar collectors for hot water preparation.

- The total heating main is 11.6 km long.

- Flue gases used to go up to 160 degrees, but now they go up to 50 degrees. The flue gas condenser removes heat from the leaving flue gases, usefully discharged into the heating network to increase the temperature, it increases the efficiency of the production process. Flue gases with a temperature of 50 degrees go into nature. It does not harm nature, now all the heat is used more efficiently.

It is important for the project to create an understanding of the factors that can affect air quality in our city, and thus the environment as a whole. We conclude that heat production in Limbaži is environmentally friendly.

Students use the information to understand how heat is produced in their city, they can talk about the use of wood chips instead of fossil fuels. The information was presented to the classmates and the school staff at a school event about the goals and issues of the environment and the PULCHRA project.